The single shaft shredder shreds the materials by pressing them against the rotor with hydraulic pressure. The fineness of the shredded materials can be adjusted by choosing the screen of your choice. The materials that can be shredded include waste plastics, construction waste, scrap textile, scrap paper, and rubber.

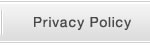

Structure Diagram

|

Pusher model with increased shredding speedA1 Hydraulic pusher A2 Hydraulic unit |

|---|---|

|

Compatible with various processing materialsB1 Fracturing motor B2 Gear motor |

|

SafetyC1 Safety Switch C2 Vibration Absorption Rubber |

Pusher model with increased shredding speed

Hydraulic pusher

The hydraulic pusher holds down materials against the rotor allowing for a stable and effective processing of objects of various shapes and materials.

- Hydraulic pushers avoid excess strain, adjusting its movement according to the load current.

- The uneven tips of the pusher prevents objects from escaping.

Hydraulic pusher pulled back

The pusher automatically moves forward and back. There are no specific timings for loading.

Hydraulic pusher pushed forward

The pusher moves in a parallel motion towards the fracturing rotor, pushing objects in.

Coolers are installed to maintain the stable movement of the hydraulic pusher. The prevention of the overheating of fuel allows for smooth operations in hot climate.

Compatible with various objects and materials

Fracturing rotor

A spinning blade is attached to the fracturing blade, which grinds down objects that have been pressured down with the pusher. Objects that are difficult to process can be shredded without excess strain by grinding them gradually.

- The spinning blade is placed to form a V, reducing the load when shredding.

- When excessive electrical current is detected, the blades will spin backwards and restart the fracturing process.

Fracturing blades

Equipped with distinctive fracturing blades, type SSG single shaft shredder thoroughly processes objects including thin plastic, textile scrap, and paper.

Process example

-

Fracturing Example

Wood

-

Plastics

-

Paper

-

Scrap Textile

-

Rubber

※ If you wish to test any materials, please do not hesitate to contact us.

Safety

Designed to avoid accidents and malfunction, type SSG single shaft shredder can be used safely for a long term.

Safety Switch

The screen basket is equipped with an access switch as it is located close to the fracturing rotor. The machine will not operate when the screen basket is open.

Should any problem occur, there are two emergency stop buttons above the switch and on the control board.

Upper switch

Control board

Vibration Absorption Rubber

Vibration will affect the consumption of objects and cause damage to the machine as well as create noise. Type SSG Single Shaft Shredder comes standard equipped with anti-vibration rubber padding on the base.

Maintainability

Type SSG single shaft shredder is a self maintaining, simple design machine made to reduce running costs. Cleaning and checkups as well as the replacing of major components can easily be done, allowing maintenance to be carried out without frequent professional assistance.

Blade replacement

The abrasion speed of the blades differ according to the processing objects, but it will affect performance. The blades are secured with a bolt, making replacement easier, as they are disposable.

from the fracturing room

from the screen

<Rotating blade>

- The blades are excellent for drawing in and shredding objects.

- Replacement is a simple process with a single bolt.

- Dulled edges can be turned 180 degrees for a rotational use.

Inspection and cleaning

Inspection and cleaning are among the most important aspects for maintenance of the machine. Type SSG Single Shaft Shredder, has been designed in such a way that is easy to clean.

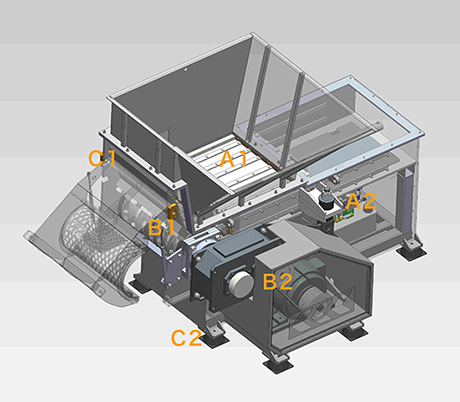

<motor cover>

A single plate is held down with bolts

Cover opened

It can be opened and closed by replacing and adjusting the v belt.

<Screen bucket>

It can be opened by removing tow bolts.

Inspection, as well as cleaning and replacing of screens, before and after operation is simplified.

Basic Specification and Custom Specification

The type SSG single shaft shredder can be adjusted in various ways to fit various users. It can, of course, be combined with other machines such as conveyers. Please do not hesitate to consult us.

Examples

With added vent and hopper. The cradle is made higher.

Lids can be added onto hoppers to prevent spilling.

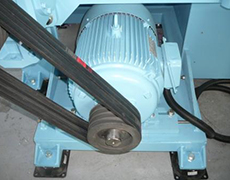

<External Form>

Type SSG Single Shaft Shredder: Specification Measurement

Model

SSG-150

SSG-350

SSG-750

Operating electric motor drive

(kw)

15

37

75

Fracturing room measurement

A×B(mm)

500×790

800×1300

500×1300

Rotor radius

(mm)

φ220×500

φ400×800

φ400×1500

Blade

Size-Number of sheets

□40-19

□40-35

□40-72

Volume

C(L)

1790

2665

2665

D(M)

1210

1800

2830

E(H)

1680

2130

2130

Weight

(kg)

1650

3800

6700

| Model | SSG-150 | SSG-350 | SSG-750 | |

| Operating electric motor drive | (kw) | 15 | 37 | 75 |

| Fracturing room measurement | A×B(mm) | 500×790 | 800×1300 | 500×1300 |

| Rotor radius | (mm) | φ220×500 | φ400×800 | φ400×1500 |

| Blade | Size-Number of sheets | □40-19 | □40-35 | □40-72 |

| Volume | C(L) | 1790 | 2665 | 2665 |

| D(M) | 1210 | 1800 | 2830 | |

| E(H) | 1680 | 2130 | 2130 | |

| Weight | (kg) | 1650 | 3800 | 6700 |

※ Please note that specifications and designs may be altered for improvement without prior notice.

Please contact us for measurements not indicated above.

.png)